Waste oil distillation

Waste oil recycling process plant

But purity and color of tire oil cannot meet the standard for cars, and it cannot be used for cars directly. On the other hand, there are many waste oil appeared due to an increasing of all kinds of vehicles , such as waste motor oil, used engine oil and lubricating oil. So distillation technology is emerged, many companies supply distillation plant for waste oil disposal.

Henan Doing produced waste oil recycling process plant can refining waste oil(waste engine oil,motor oil, tyre oil, plastic oil etc) to clean diesel. The oil recovery yield is about 85% ( according to oil quality).

How to recycle used oil to diesel fuel ?

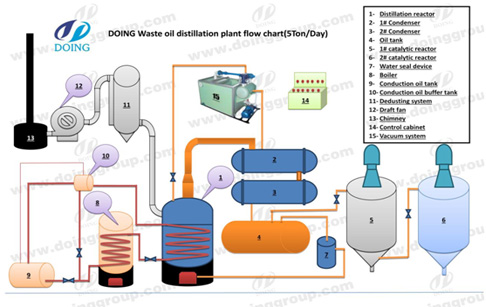

Waste oil recycling process plant working process

1. Pump raw material into distillation reactor by oil pump. Then close the feeding inlet to totally sealed. (Continuous plant adopts automatic feeding device);

2. Use coal/wood/natural gas/fuel oil/electricity to heat the reactor, and the liquid oil will slowly become oil gas, which will be liquefied into fuel oil by the cooling pipe and condensers and then go into oil tank. For getting higher quality diesel, you are required to control the temperature over 150 Celsius degrees. When the temperature decreases to below 150 Celsius degrees, the gasoline will be cooled out;

3. Some gases like Methane, Ethane, Propane, Butane cannot be liquefied will be recycled into the furnace for heating the reactor;

4. It will produce some smoke when fuel materials are burnt. The smoke will be processed by dedusting system completely;

5. The exhaust gas will go into the chimney sucked by draft fan, before emission the exhaust gas will become steam, no pollution.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating no waste emission.

- 4.Auto welding to ensure life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do project plan,including financial analysis.

Help customer finished

delivery,foundation,installation,trainning,commissioning and try

running.

One year warranty period .

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: