Pyrolysis plant

Waste tyre

Waste tyre oil extraction machine

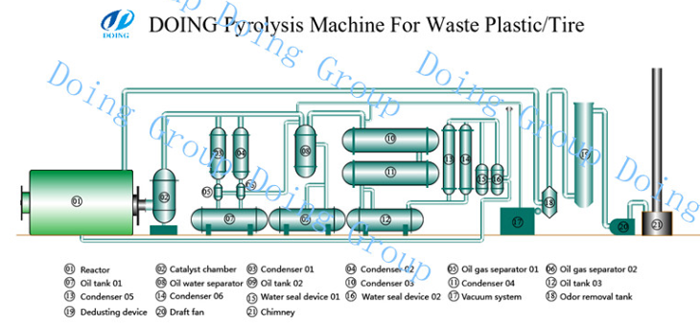

Waste tyre oil extraction machine working process

Second, start the waste tyre oil extraction machine reactor will rotating and be heated. When the inside temperature reaches the degree of 250 to 280, the oil gas will begin to generate while flow through oilgas separator, and continuously produce until the temperature up to the degree of 350 to 460.

Third, in oil gas separator, light component will enter the condensers, meanwhile, heavy component will be liquefied and then automatically discharged into heavy oil tank.

Forth, most of the light component will be liquefied through condensers to crude oil.

Small amount of oil gas cannot be liquefied and will be transferred by water seal tank back to the burning.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating no waste emission.

- 4.Auto welding to ensure life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do project plan,including financial analysis.

Help customer finished

delivery,foundation,installation,trainning,commissioning and try

running.

One year warranty period .

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: