Waste oil distillation

Crude oil fractional distillation machine

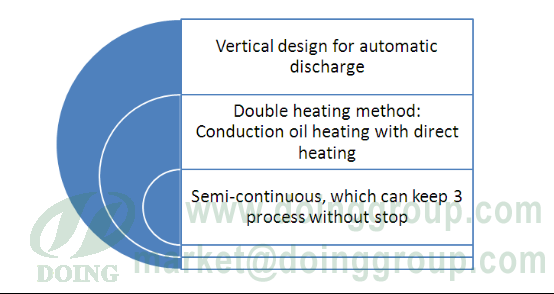

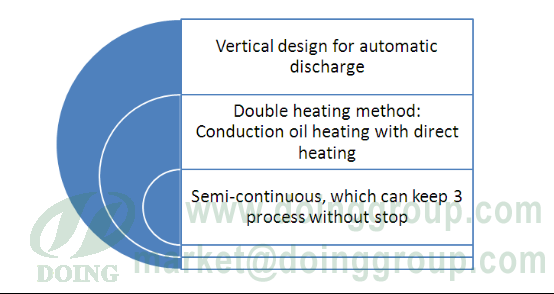

Compared to the old design horizontal type distillation machine, our new design crude oil fractional distillation machine adopts vertical design with conduction oil heating method.

Since the heating for old design horizontal type crude oil fractional distillation machine is only from the bottom, which takes too long time to finish the process. Our new design distillation machine adopt conduction oil heating with bottom fuel heating together, which can save half time for heating. And our distillation machine is vertical design, which can make the slagging automatically without manual work.

For old design horizontal type crude oil fractional distillation machine, slagging can only from the feeding door by manual and it’s very difficult and takes long time. Because after distillation process, the residues left in the distillation machine is asphalt, which is liquid when hot, and become solid when cold. So you have to discharge it when it’s hot. But it’s very dangerous for the workers and not easy to be taken out. So the vertical design distillation machine with automatic slagging method is becoming more and more popular in the market.

If you want to know more details about our crude oil fractional distillation machine, please feel free to contact us.

Since the heating for old design horizontal type crude oil fractional distillation machine is only from the bottom, which takes too long time to finish the process. Our new design distillation machine adopt conduction oil heating with bottom fuel heating together, which can save half time for heating. And our distillation machine is vertical design, which can make the slagging automatically without manual work.

For old design horizontal type crude oil fractional distillation machine, slagging can only from the feeding door by manual and it’s very difficult and takes long time. Because after distillation process, the residues left in the distillation machine is asphalt, which is liquid when hot, and become solid when cold. So you have to discharge it when it’s hot. But it’s very dangerous for the workers and not easy to be taken out. So the vertical design distillation machine with automatic slagging method is becoming more and more popular in the market.

If you want to know more details about our crude oil fractional distillation machine, please feel free to contact us.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating no waste emission.

- 4.Auto welding to ensure life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do project plan,including financial analysis.

Help customer finished

delivery,foundation,installation,trainning,commissioning and try

running.

One year warranty period .

上一篇: How to clean used motor oil for fuel?

下一篇: What is the final froduct of crude oil distillation equipment?

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: