Pyrolysis oil refining process distillaton plant

Pyrolysis oil refining process distllation palnt

Pyrolysis oil refining process distillation plant

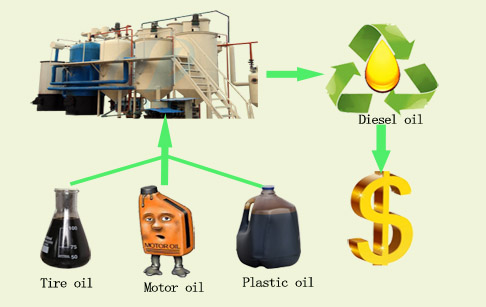

Although we can get pyrolysis oil from waste tyre, rubber or plastic by waste tyre pyrolysis plant .it seems lots of people would like to pursue higher quality oil, like diesel and gasoline. Thereby, the pyrolysis oil refining process distillaton plant becomes a very hot and highly profitable green project, which cost low, collect raw material easily and convert pyrolysis oil to diesel or gasoline efficiently (oil recovery rate is about 90%).

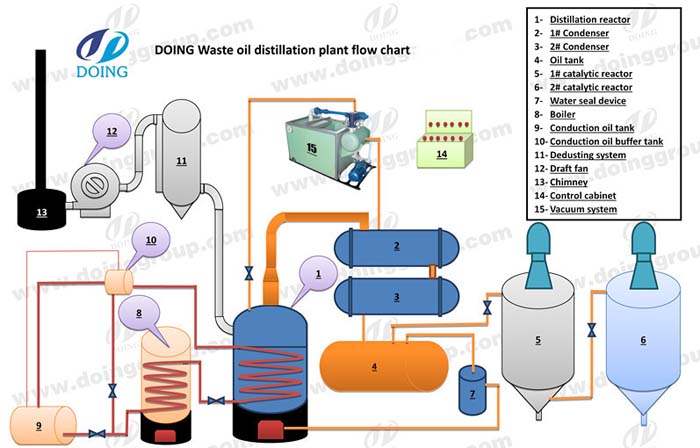

Pyrolysis oil refining process distillation plant working process

Pyrolysis oil refining process distillation plant

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The diesel will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system

Pyrolysis oil refining process distillation plant advantage

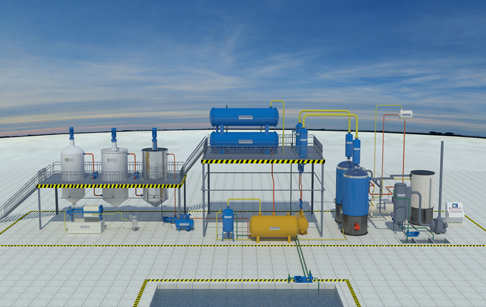

Pyrolysis oil refining process plant 3 D picture

High production yield: the raw material recovery ratio is about 90%. When the water content is less than 5%, the ratio can even exceed 90%.

1. High on-stream efficiency without corrosion, fouling, and coking.

2. Auto feeding and slag discharging assists the pyrolysis oil distillation equipment/plant in achieving continuous running for the whole day.

3.Featured with environment protection operation tech and devices. In and after the process, no soil, water or air pollution exists.

4.The most cost-effective oil refining to diesel technology in China.

5. It is easy for the pyrolysis oil distillation plantto clean and maintain with vertical structure.

6. The system creates an alternative of energy to replace petroleum products and natural gas.

We can get diesel fuel by waste pyrolysis oil refining process plant ,the diesel fuel can used tractors, trucks, ships and diesel oil generators etc.

Diesel fuel application

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: Nothing

Next article: Turn plastic into diesel plant

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: