Waste oil to diesel conversion plant

DOING recycled waste solid to oil plant which adopted advanced technique and machine design can split waste tyres & plastic & rubber into black plastic fuel oil (after catalytic pyrolysis will get high quality diesel). From DOING recycled waste solid to oil plant we can get higher oil output.Like black fuel oil rate is about 45%-90%. And diesel oil recovery rate can be 85%- 90% with waste oil to diesel conversion plant.

Waste oil to diesel conversion plant

Our latest technology for recycling waste solid oil to diesel fuel, also named waste oil to diesel conversion plant can recycle black oil into non-standard diesel fuel and the remaining is asphalt. How to recycle black oil into diesel fuel?

First, to pump black plastic fuel oil into waste oil to diesel conversion plant.

Second, we need to heat black plastic fuel oil and keep it in a best temperature for best diesel quality. Fuel oil will be converted to diesel oil gas when get heating.Then our cooling system will cool diesel fuel oil gas into diesel fuel.

Next pump diesel fuel oil into odor and color removal system for remove which will purify further diesel fuel with special catalyst.

Finally, you can get 85% diesel from our waste oil to diesel conversion plant.

Waste oil to diesel conversion plant

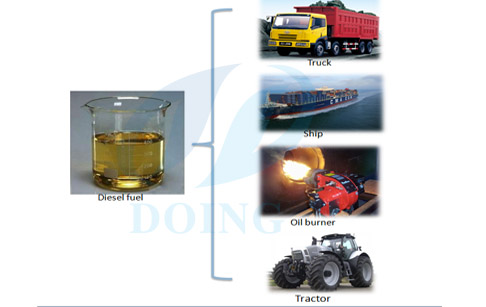

Diesel fuel got from waste oil to diesel conversion plant can be used in the diesel engines found in most freight trucks, trains, buses, boats, and farm andconstruction vehicles. Some cars and small trucks also have diesel engines.Diesel fuel is used in diesel engine generators to generate electricity. Mostremote villages and other locations, use diesel generators to supplyelectricity. Many industrial facilities, large buildings, institutional facilities, hospitals, and electric utilities also have diesel generators forbackup and emergency power supply.

Diesel fuel application

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Previous article: Diesel from plastic waste plant

Next article: Pyrolysis fuel oil refinery plant

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: