Recycling machine

Reactor is the main part of the recycling machine, it determines the service life of the whole recycling machine. So reactor’s quality is very very important in the whole recycling machine line . It not only determine the service life of the reactor, but also determine the safety, because the whole recycling machine line only here have thefire and pressure.

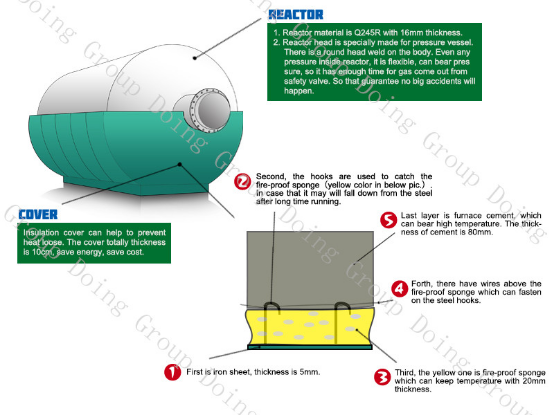

Draft reactor of recycling machine

How we ensure our recycling machines' reactor’s quality? We do from the beginning. We have laboratory testing the quality of steel. Every time we buy steel, we must test them in our laboratory to see whether it is standard Q245R boiler plate. In our laboratory, there are steel impact test cryogenic tank, steel plate tensile test, steel impact tester and so on all for testing the quality of the steel. Then we have the fully automatic CNC laser cutting machine to cut the steel and use the submerged automatic arc welding to weld the steel automatically. Then use the X-ray test for welding crack line. Once get through, then we go on. So we are very sure about our recycling machines’ quality, usually the reactor can use 5-8 years.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating no waste emission.

- 4.Auto welding to ensure life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

上一篇: Is there catalyst in your tire recycling machine?

下一篇: Does the waste tyre recycling plant pollution Environment?

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: