Pyrolysis plant

Introduce Doing pyrolysis plant working principle.Doing pyrolysis plants pyrolysis raw material (waste tire/tyres,waste plastic,rubber etc.) as follows:

Firstly, put the raw material into furnace

Secondly, burn the fuel material(coal, or wood, or natural gas, or oil ) in the combustion system. After finishing oil producing, the temperature of reactor will come down, at the same time, carbon black will be discharged automatically.

Lastly, when the temperature falls to 100 degree celsius, worker could open the door of the reactor to discharge the steel wire.

Then can start another batch.

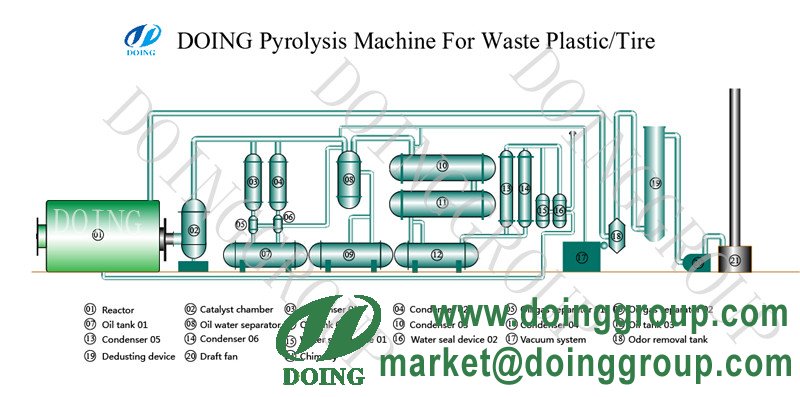

Pyrolysis plant working flow chart

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating no waste emission.

- 4.Auto welding to ensure life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do project plan,including financial analysis.

Help customer finished

delivery,foundation,installation,trainning,commissioning and try

running.

One year warranty period .

上一篇: Oil from waste tyre pyrolysis plant is easy for sale?

下一篇: How is product and raw material market of pyrolysis plant?

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: