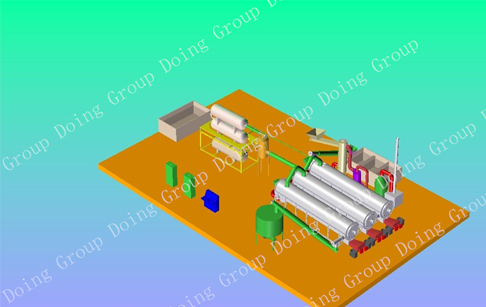

Fully automatic waste tire pyrolysis plant

Doing have a technologically developed fully automatic waste tire pyrolysis plant, which is used for generating energy from the waste tires. These fully automatic waste tire pyrolysis plant are efficient way for disposing of such non biodegradable waste, where the organic materials is heated in the absence of oxygen or other reagents that produces gas, oil, carbon black and steel. Our fully automatic waste tire pyrolysis plant is also capable of treating the rubber and industrial plastic waste.

Fully automatic waste tire pyrolysis plant

a.Heating in advance to make the temperature of the reactor rises up to about 300℃, fuel choose can be gas or oil.

b.Turn on the auto-feeder, small pieces of tyres loaded into reactor and pyrolysis begins; reaches certain temperature and the gas oil is generated from the waste.

c.oil gas generated and condensed into fuel oil stored, sync gas recycled and used as fuel during operation; at the same time, carbon black and steel wires in short also discharged from the auto-discharging system. The Steel metal and carbon black separated automatically and stored.

d.Since one batch begins, it lasts for about 20days continuously, without any stop.

e.Then stop the motor, and do the maintenance.

The next batch of process begins again.

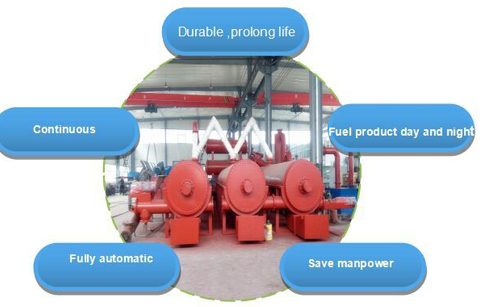

DOING fully automatic waste tire pyrolysis plant feature

DOING fully automatic waste tire pyrolysis plant feature

2.Automatic ejiecting wastes residue

3.Fuel product day and night

4.Safe operation ,save manpower

5.Production efficiency.improve efficiency

6.Durable ,prolong life

Fully automatic waste tire pyrolysis plant final product and usage

Fuel oil application

●Environment-Friendly, Pollution Free.

●High Efficiency Cooling Condensers.

●Raw Materials: Tires (Shredded into small pieces)

B. Facilities

●Power: about 60kw/H

●Water Required (Recycled): 40MT (about)

●Installation space required: 48m*20m

C. Employees

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: Advantages of continuous waste tire pyrolysis plant

Next article: Plastic to fuel oil conversion machine

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: