Waste tyre to fuel oil energy machine

Waste tyre to fuel oil energy machine

Principle introduction of Eco-friendly waste tyre to fuel oil energy machinee:

Pyrolysis is thermochemical decomposition of waste tyre polymer, since waste tyre are long chain polymers containing more than 50,000 carbon atoms. The process will require an initial fuel source of coal, wood or oil. Oil gas produced flows through several successive condensers where the gas is cooled and oil gas is condensed into oil.

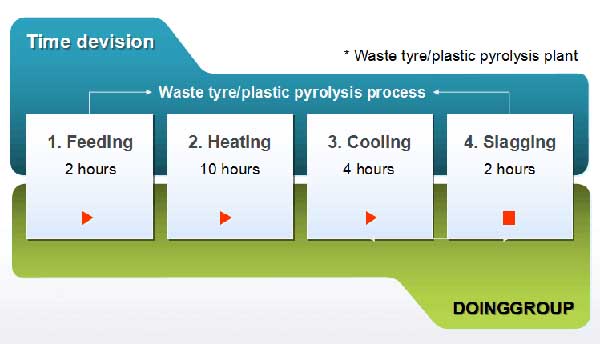

Working process of Eco-friendly waste tyre to fuel oil energy machine:

|

Processing time |

|||||

|

Model |

Load tires into reactor (hour) |

Preheating time (hour) |

Oil gas output time (hour) |

Reactor cooling time (hour) |

Carbon black steel wire discharging (hour) |

|

DY-1-10 |

2 |

2 |

8-10 |

3-4 |

2 |

Advantage of Eco-friendly waste tyre to fuel oil energy machine:

Waste tyre to fuel oil energy machine

A. Rich experience:equipment had exported to more than 18 countries.

B. With ISO9001:2008,CE Certificate.

C. Strict requirements for quality:

IQC:Incoming quality control,main raw material;

PQC:Process quality control,All the reactor is inspection by X-ray.

D. Running machine available for customer visit.

E. Factory area : 20000 square meter.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Previous article: Waste plastic to fuel oil energy machine

Next article: Nothing

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: