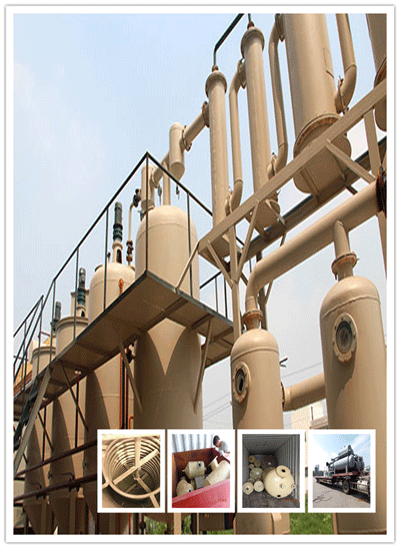

Waste oil distillation plant

The shining plant in below picture is Waste Oil Distillation Plant, this one is 10ton capacity, the master piece of Henan DOING Mechanical Equipment Co. Ltd, which is among the best sellers during year 2014.

waste oil distillation plant

Compared with Tire/Plastic Pyrolysis Plant.Waste oil distillation plant is also composed of over one thousand components with different sizes, some are large, otitss are precise. Among the large units, most are patented products. What is more, she is qualified with BV, CE, ISO, and SGS, proving its safety and quality insurance. Safety and quality issues are always the most concern of Henan DOING Mechanical Equipment Co., for every worker’ life is incomparable.

5ton waste oil distillation plant

Without doubt, waste Oil Distillation Plant was born with a large number of unparalleled edges. Security, it is employed with at least three large safety device, which are connected with the reactor and cooling system, in order to prevent syngas from going back to the reactor causing accidental explosion; besides, some safety valves are operating togetits with the alarms to keep the reactor running under normal pressure in case the workers were absent of the site. Energy-saving, used circular water from the cooling system and syngas both can be recycled to save a lot of fuel energy and clean water, thus reducing a large amount of cost for clients. Environmental friendly, chemical water is used in dust-removing system to cleanse the smoke until it turns into steam, and waste water from the cooling system and syngas from burning processing both can be recycled to the reactor and go back to the cooling system, such as heating the reactor and run as circulating cooling water again; so far, air and water pollution are avoided.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: Waste oil refining machine

Next article: Waste engine oil refining to diesel equipment

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: