The 6th generation turn waste tyre to oil equipment

The 6th generation turn waste tyre to oil equipment is the newest product of our company, it is the most advanced tyre to oil pyrolysis plant on the market now. Compared with our previous products, 6th generation turn waste tyre to oil equipment has many advantages, let’s see it together.

The 6th generation turn waste tyre to oil equipment

Advantages of the 6th generation turn waste tyre to oil equipment:

1. Less floor space

With our special design, Doing 6th generation turn waste tyre to oil equipment does not need subgrade since we add an apyrous pedestal under the reactor to replace the subgrade, it can save our clients lots of land and civil engineering cost.

2. 3 to 5 times service lifes

At before, the reactor service life is decreasing day by day due to thermal expansion principle, now we add a special equipment inside the reactor and it is hot air heat the reactor. The service life is 3 to 5 times than before. On the other hand, the heating energy can get 100% utilization.

3. Fully environmental friendly

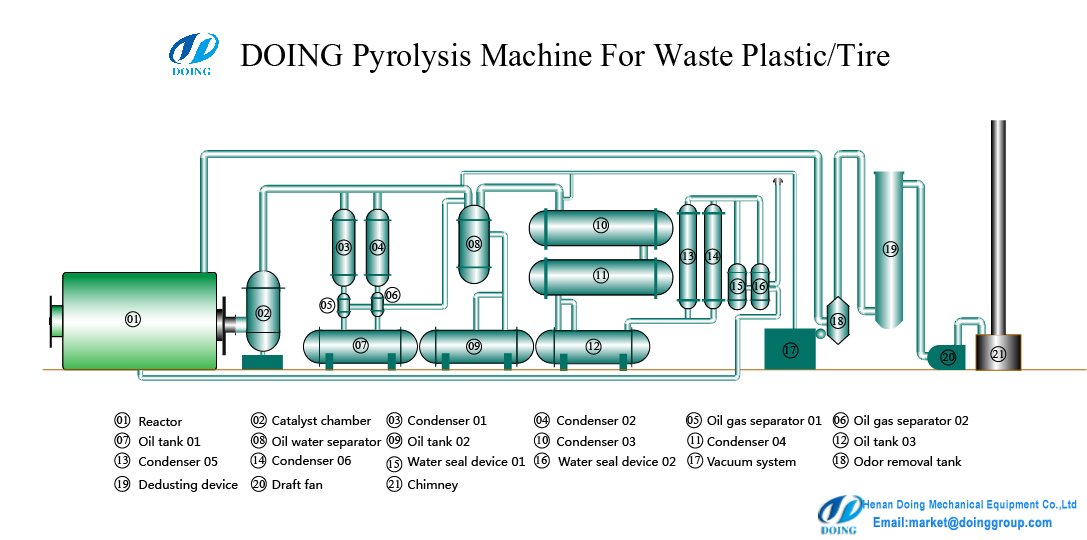

There is a dust removal system connect to the top of the reactor, the dust remover adopts cyclone de-duster and filter bag de-duster composite design, it can guarantee the best environmental dust removing effect. Another feature of the de-dusting system is that it does not need de-dusting pool.

4. Condensing system

The condensing system of tyre to oil pyrolysis equipment decides the oil yield on a large extent. Our newest tyre to oil pyrolysis equipment still adopts three steps cooling system, but now we use four six meters big horizontal condensers, and still another two vertical condensers to guarantee the oil quality and yield.

5.High value by-products

Carbon black could be made into pellets with our carbon black process device, you could sell carbon black pellets into factory to make pipes or used to other plastic or rubber products. It is very profitable.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: Furnace oil from used tyres machine

Next article: High oil recover waste tyre pyrolysis to oil plant

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: