Waste tyre recycling plant machinery

Waste tyre recycling plant machinery

Waste tyre recycling plant machinery raw material

Waste tyre recycling plant machinery

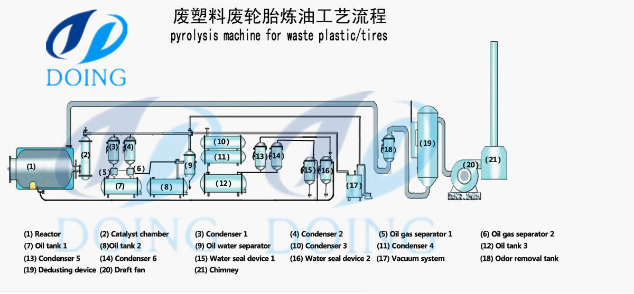

Working processes of waste tyre recycling plant machinery are as following:

Waste tyre recycling plant machinery

1. Make reactor rotate clockwise 0.4r/min, put waste tyre into reactor, close feeding door.

2. Burned the fuel material (coal, wood, natural gas or oil) in the furnace. Reactor will be slowly heated, when the temperature reach around 180℃, oil gas will come out, then go to cooling system and get liquid oil. Some incondensable gas which can’t cool down will be lead to furnace through a gas pipe. It will be used to heat reactor which can save your energy. Only the first 2 hours use energy for heating. After the first 2 hours mainly use gas, little energy is OK. After pyrolysis, all the oil gas come out from reactor, the temperature will fall down. Then make it rotate anticlockwise, carbon black discharging begin.

3. When the temperature deduce to 50℃, worker can opened the door of reactor take steel wire out.

4. And then you can start the next batch.

The output of waste tyre recycling plant machinery:

Main products from waste tyre recycling plant machinery

Take 10T waste tyre recycling plant machinery for example:

a. Crude oil: 45%*10t=4.5t

b. Carbon black: 30%*10t=3t

c. Steel wire: 13%*10t=1.3t

a. Crude oil: 45%*10t=4.5t

b. Carbon black: 30%*10t=3t

c. Steel wire: 13%*10t=1.3t

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: Recycling plastic bottles to fuel oil machine

Next article: Used plastic recycling machine

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: