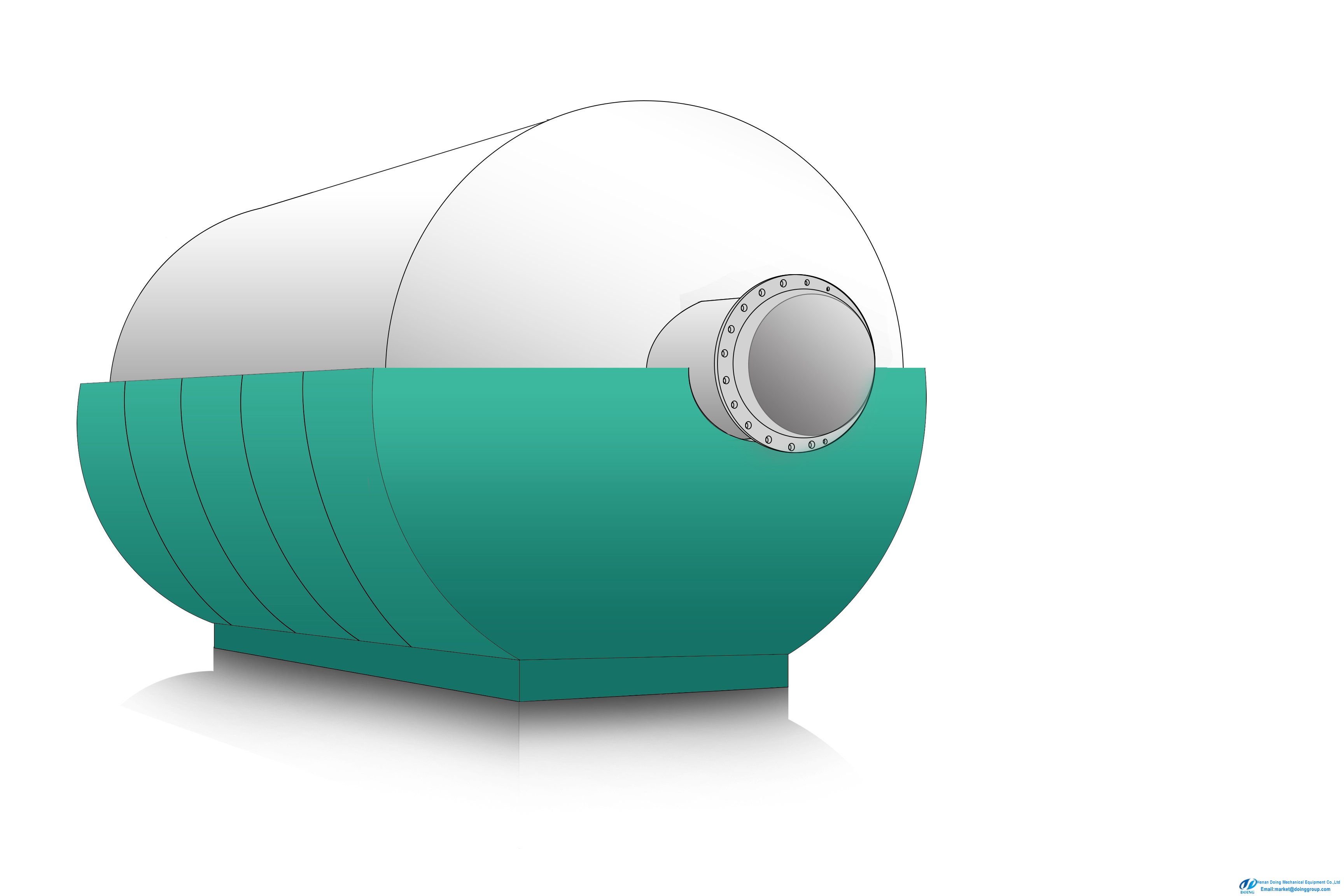

Waste recycling pyrolysis plant

Waste recycling pyrolysis plant is mainly disposal of waste tire, waste plastic,waste rubber to fuel oil, carbon, the oil yield is about 40%-90%( depends on waste material like tire,plastic).

Waste recycling pyrolysis plant

Pyrolysis process of Recycling Pyrolysis Plant:

First: with 60 ton hydraulic pressure, waste tire/ plastic can be pushed to the reactor.

Second: Oil gas will be generated in the reactor after burning for 2-3hours and then go into the catalyst chamber to get purified.

Third: The purified oil gas rise up and go into the condenser pipe for first condensing. The oil gas liquefied here and flow into the oil-water separator.

Fourth: 70% of heavy oil will be collected the oil tank. The rest oil gas will go into the horizontal condenser to be condensed for the second time. 30% light oil can be separated here.

Fifth: Little remaining oil gas will come to the tail gas recycling device to be condensed for the last time. Here we can get 20-30kg oil to ensure all the oil gas liquefied.

Finally: The exhaust can be recycled as fuel resource to the burning furnace, creating a situation: burning coal for earlier stage and exhaust during later period.

Waste recycling pyrolysis plant features:

As we all know, the quality of reactor directly determines that of whole equipments. Durability can be guaranteed by the following distinctive design.

• No requitements for raw material with compound feeding ports.

• Decompress automatically with safety valve.

• Adopt I-beam steel for the base to make it strong enough.

• Special insulation makes good heat preservation and thus energy-saving.

• Made with Q245R boiler plate and welded automatically to obtain durability.

• Easy to feeding and slagging with built-in spiral plate.

• A special anti-blocking device to eliminate potential security risk.

• Easy to clean and maintain with standard gear screwed on reactor instead of welding.

• Keep stable after long time heating as supported by roller at exact place.

• Expanding oil outlet to distribute pressure and thus durable.

Waste tire disposal pyrolysis reactor

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: 10Ton tyre to oil recycling pyrolysis plant

Next article: Plastic recycling process machine

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: