Convertion of waste plastic into fuel process machine

Convertion of waste plastic into fuel process machine

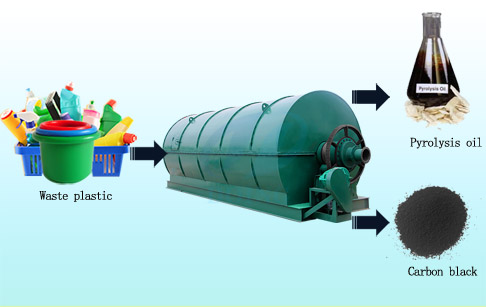

The convertion of waste plastic into fuel process machine method is a new technique which heats whole or shredded plastic in a reactor vessel containing an oxygen free atmosphere and a heat source,In the pyrolysis reactor the plastic is softened after which the plastic polymers continuously breakdown into smaller molecules.These smaller molecules eventually vaporize and exit from the pyrolysis reactor.These vapors can be burned directly to produce power or condensed into an oily type liquid, generally used as a fuel.

Convertion of waste plastic into fuel process machine

Some molecules are too small to condense. They remain as a gas which can be burned as fuel.The minerals that were part of the plastics , about 40 to 45 % by weight, are removed as a solid.When performed well a plastic pyrolysis process is a very clean operation and has nearly no emissions or waste.

The properties of the gas, liquid and solid output are determined by the type of feed stock used and the process conditions.

For instance whole plastic contain fibers and steel. Shredded tyres have most of the steel and sometimes most of the fiber removed.Batch wise Process is done by plastics pyrolysis.

The remaining solid material, often referred to as "charcoal"(carbon black).

Convertion of waste plastic into fuel process machine working process

1. Put raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

Last, when the temperature falls to 100 degree Celsius, worker could put steel wire hook to reactor to take steel wire out. After all these steps, you can start another batch.

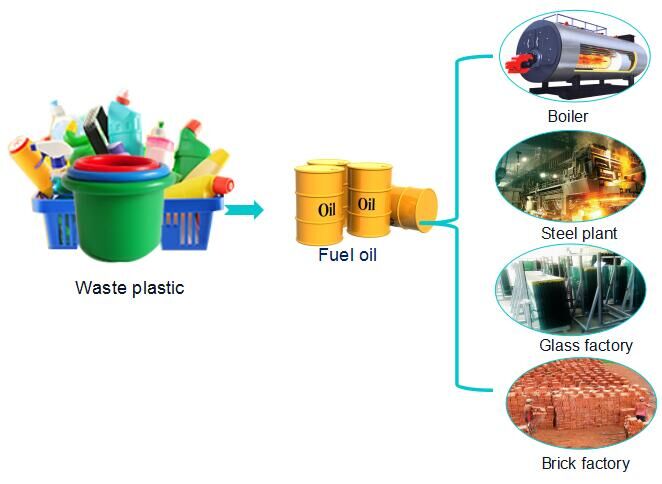

Fuel oil application of convertion of waste plastic into fuel process machine

Fuel oil application

This fuel oil of convertion of waste plastic into fuel is crude fuel oil, which can be used for industrial heating used in any fuel needed industrial factories, such as cement plant, steel mill, glass factory, brick factory, boiler used factory, etc. Or can be refined to diesel, directly used in diesel burners, generators, heavy trucks, agricultural machinery, and mix with normal diesel used for cars.- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: Tyre to oil recycling process plant

Next article: Pyrolysis machine for waste disposal recycling tires plastics

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: