Waste tyre pyrolysis plant

Better Diesel Extraction!!! waste tyre pyrolysis plant,pyrolysis plant without sulfur

Waste tyre pyrolysis plant |

Waste tyre pyrolysis plant without sulfur can convert waste tires, waste plastic, waste rubber to fuel oil, carbon, steel wire. Waste tire oil average rate is 45%-52%, plastic is 75%-95% for PP,PE,ABS etc. |

Oil distillation machine |

Oil distillation machine can process waste engine oil, motor oil, black oil, tire oil, plastic oil to clean diesel. This kind of diesel can be used to tractors, trucks, diesel oil generator, power generator etc. Oil recovery average rate: 75%-90%. |

Waste tyre pyrolysis plant without sulfur working pinciple description briefly

a> Firstly, the raw material was put into furnace with auto feeder,thenseal the feed inlet system.

b> Secondly, burned the fuel material (coal, or wood, or natural gas, oil ) in the combustion system .The reactor will slowly heat, when the temperature reach around 150 degree Celsius, it will produce oil gas .

c> Oil gas will be processed by our technology ,then gone to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure ,which will be designed to back to combustion system to instead the fuel material to burn the reactor .which can save energy very much.

d> After finished oil produce ,the temperature of reactor will be down ,in same time ,carbon black will be discharged automatically.

e> Lastly, when the temperature fall to 100 degree Celsius, worker could opened the door of reactor to discharge of steel wire .

f> Then can start to another batch working.

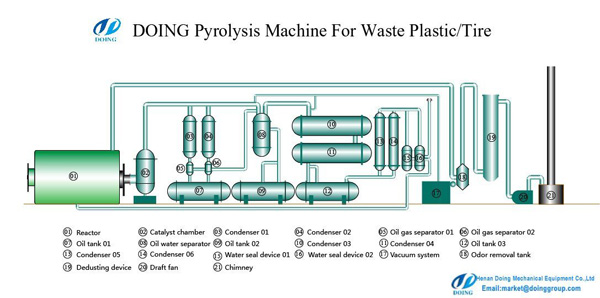

Flow chart of waste tyre pyrolysis plant process

a> Auto-feeder - To shorten feeding time; feed more raw material; save workers,save time,save energy.

b> Reactor - Q245R/Q345R material , pyrolysis for waste tire / waste plastic / waste rubber.

c> Buffer chamber - To reduce oil gas speed; improve oil quality.

d> Oil-water separator - Avoid oil gas reback to reactor, ensure running safety.

e> Cooling system (Vertical condensers and horizontal condensers) -100 squre meter better condensing effect to get more.

f> Oil tanks - Collect tire/plastic oil.

g> Anti-back fire device - First to recycle tail gas to furnace as fuel; second water closing for machine running safety.

h> Negative pressure device - Guarantee working under normal pressure safety; shorten pyrolysis time; environment protection.

i> Dust removal system - ensure the smoke reach international emission standard.

j> Bad mell removal system - Remove bad mell,keep a well environmental working place, to ensure reach international emission standard.

k> Carbon black slagging device - Slagging carbon black automatically, environmental protection; save time and workers.

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Previous article: Waste plastic pyrolysis plant

Next article: Nothing

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: