Waste tyre pyrolysis process plant

Waste tyre pyrolysis process plant

Waste tyre pyrolysis process plant technolical data

| Technical parameter of Waste tyre pyrolysis plant | ||||

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tire | Waste tire | Waste tire |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Waste tyre pyrolysis process plant final product application

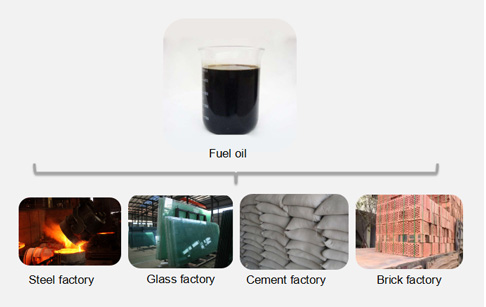

Fuel Oil (45% to 52%)

Fuel oil application

Carbon Black (30%)

Carbon black application

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: High Profits Waste Tire Recycling Pyrolysis Plant

Next article: Waste tyre recycling pyrolysis plant for sale

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: