-

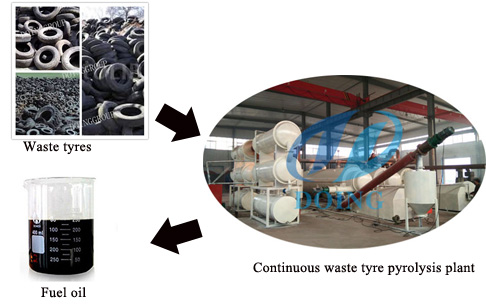

Waste plastic to fuel conversion plant

Waste plastic to fuel conversion plant

Waste plastic to fuel conversion plant

The waste plastic to fuel conversion plant is a kind of environmental protection product that can convert the waste plastics to the useful fuel oil, which adopts the new green technology. Not only the oil produced by the price plastic waste pyrolysis -

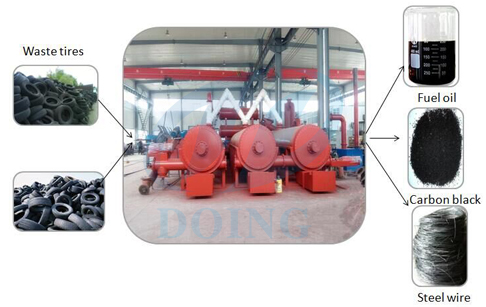

Tyre to oil recycling process plant

Tyre to oil recycling process plant

Tyre to oil recycling process plant

The tyre to oil recycling process plant is low because the plant can effectively convert waste tyre into fuel oil, carbon black and steel wire. The raw materials are easy to collect and the final products have high economic value. -

Automatic fully continuous waste tyre pyrolysis plant

Automatic fully continuous waste tyre pyrolysis plant

Automatic fully continuous waste tyre pyrolysis plant

Automatic fully continuous waste tyre pyrolysis plant is the new design of pyrolysis plant.Compared to batch pyrolysis plant. Automatic fully continuous waste tyre pyrolysis plant can run automatically and continuously. It will help you to -

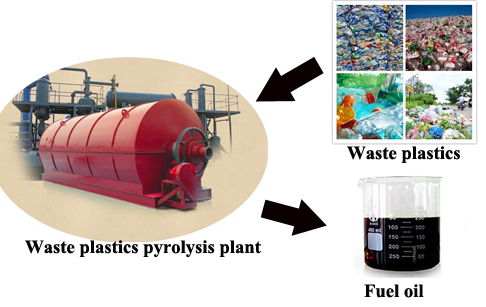

Plastic to fuel oil conversion machine

Plastic to fuel oil conversion machine

Plastic to fuel oil conversion machine

Plastic to fuel oil conversion machine is to conver waste plastic into fuel.The raw material of plastic to fuel oil conversion machine is waste plastic , waste tyre ,waste rubber and so on .After pyrolysis of machine change plastic to oil ,we can get -

Fully automatic waste tire pyrolysis plant

Fully automatic waste tire pyrolysis plant

Fully automatic waste tire pyrolysis plant

Doing have a technologically developed fully automatic waste tire pyrolysis plant, which is used for generating energy from the waste tires. These fully automatic waste tire pyrolysis plant are efficient way for disposing of such non biodegradable was -

Advantages of continuous waste tire pyrolysis plant

Advantages of continuous waste tire pyrolysis plant

Advantages of continuous waste tire pyrolysis plant

Waste tire pyrolysis plant is the equipment line which can process waste tires to fuel oil, carbon black and steel wire for further use. As the vehicle increasing with the improving living standard, more and more waste tires generated every day. And -

Continuous waste tire pyrolysis plant

Continuous waste tire pyrolysis plant

Continuous waste tire pyrolysis plant

For continuous waste tire pyrolysis plant main raw material is waste tire/tyre.which can be easily available in and part of the world. The raw material is cheaper and can use waste tire ,we get out put from waste as fuel oil,carbon black ,steel wire. -

Pyrolysis plant reactor

Pyrolysis plant reactor

Pyrolysis plant reactor

The material of our reactor is can be Q245R,Q345R boiler plate or 304 and 304 stainless.The thickness of the whole reactor plate is 16mm.Our reactor is manufactured exactly according to the standard of pressure vessel.The cap of the reactor -

Fully continuous waste tyre pyrolysis plant

Fully continuous waste tyre pyrolysis plant

Fully continuous waste tyre pyrolysis plant

The second product of fully continuous waste tyre pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigmen