Fully automatic continuous tyre pyrolysis plant

No pollution fully automatic continuous tyre pyrolysis plant

No pollution fully automatic continuous tyre pyrolysis plant is a significant improvement based on the existing intermittent pyrolysis plant at home and abroad, continous automatic plastic pyrolysis tyre fully realize the automatic operation ,continous automatic tyre pyrolysis plant Reactor than the intermittent pyrolysis plant can prolong life 5-6 year.No pollution fully automatic continuous tyre pyrolysis plant can pyrolysis waste tire, waste plastic,used oil and waste rubber, the outcome is crude oil and carbon black without pollution. If the raw material is waste tyre, it can also output steel wires. All the products are used widely, in hotels,restaurants,bathing centers,power plants,engines,chemical sector etc.so you can sell them directly.

No pollution fully automatic continuous tyre pyrolysis plant feature

Fully automatic continuous tyre pyrolysis plant feature

2.Automatic ejiecting wastes residue

3.Fuel product day and night

4.Safe operation ,save manpower

5.Production efficiency.improve efficiency

6.Durable ,prolong life

No pollution fully automatic continuous tyre pyrolysis plant final product application:

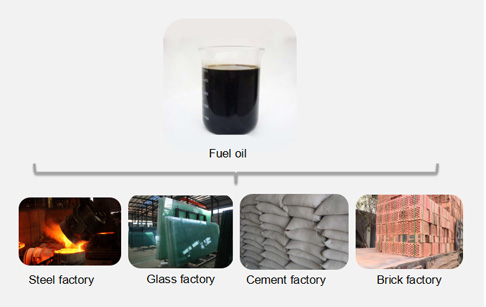

1). The Usage of Final Production ------Fuel Oil

Fuel oil application

Fuel oil from waste tyre are used in below industries:

A. Power plant factory

B. Glass factory

C. Cement factory

D. Ceramic factory'

E. Aluminum factory

F. Boiler factory

G. Central heating factory

H. Painting factory

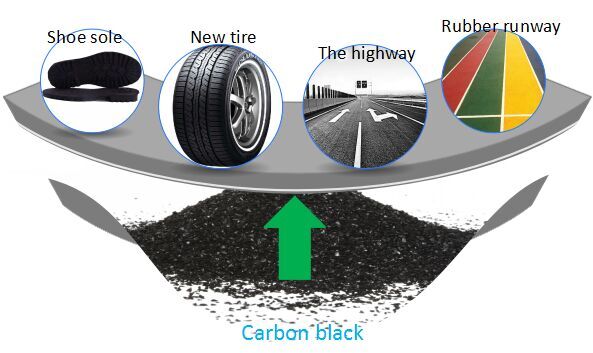

2). The Usage of Final Production ------ Carbon Black

Carbon black application

A. Electric cable jacketing

B. Conveyor ban

C. Hose and doormat

D. Black nylon bag

E. Rubber additive

F. Automatic spare parts

G. Heat Isolation

H. Black colorant in rubber materials

I. Plastic pipes

J. Industries rubber products

K. Fire fighting

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Help customer do machine that turns plastic back

into

oil project plan,including financial analysis.

Help customer finished machine that turns plastic

back

into oil delivery,foundation,installation,trainning,commissioning and

try

running.

One year warranty period .

Previous article: Waste plastic tyre pyrolysis plant

Next article: Plastic waste recycling pyrolysis plant

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: