Carbon black from waste tyres to fuel oil pyrolysis plant

Waste tyre to fuel oil pyrolysis plant

DOING revolutionary Pyrolysis Technology can really convert waste tyre into wealth. How is it possible? Because from waste tyres, you can get fuel oil, carbon black and reclaim the steel wire. Tyre fuel oil, tyres carbon black and tire wire all can bring you handsome profit. Today I am writing to mainly elaborate the application of carbon black from DOING waste tyres to fuel oil pyrolysis plant.

From the table below you can see the end products got from our waste tyres to fuel oil pyrolysis plant and their respective usage. Carbon black is the second main product from waste tyres to fuel oil pyrolysis plant. So it is very important to know the market of the carbon black from waste tyres to fuel oil pyrolysis plant.

The end products from waste tyres to fuel oil pyrolysis plant:

| NO | Carbon black from waste tyres to fuel oil pyrolysis plant Name | Percentage(%) | Usage |

| 1 | Tyre oil | 40~45 | * can be sold directly. |

| * can be as fuel. | |||

|

2 |

Carbon black | 30~35 | * can be sold directly. |

| * Process into pellets used for industrial heating or make fine carbon by use carbon black refiningmachine. | |||

| 3 | Steel wire | 12~15 | can be sold directly. |

| 4 | Sync gas | 5 | * can be recycled as auxiliary heating fuel |

From our experience and customers' feedback, the general applications of the carbon black from waste tyres to fuel oil pyrolysis plant are as follows:

Carbon black application

1.Sold directly to cement factory, because to make cement needs coal and ash, carbon black can greatly sustitute coal, and also contains ash.

2.After grinding, sold to cement factory, the price will be relatively higher.

3.After grinding to 370M, sold to painting factory.

4.After grinding, sold to rubber factory for remaking tyre and shole sole,

5.Procesing carbon black from waste tyre to fuel oil pyrolysis plant into carbon pellets used for industrial heating.

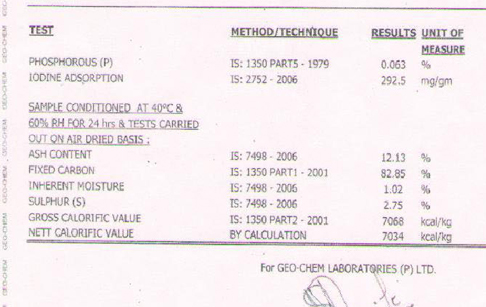

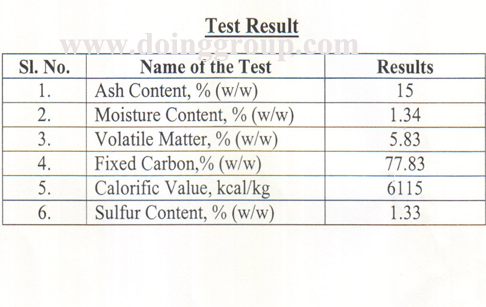

Below is the testing report of carbon black from waste tyres to fuel oil pyrolysis plant:

Testing report of carbon black

- 1.High oil yield;no bad smell during process.

- 2.Enough safety systems;normal pressure.

- 3.Recycled tail gas to heating machine that turns plastic back into oil;no waste emission.

- 4.Auto welding to ensure machine that turns plastic back into oil life, service life will be 8-10years.

- 5.Excellent service(pre-service,selling service,after-sale-service).

Previous article: Tyre derived fuel oil recycling plant

Next article: Advanced waste plastics/tyres/rubber into fuel recycling pyrolysis plant

If you are intrested in investment machine that turns plastic back into

oil ,or any other questions,such as project report,project cost,you can

leave a message in below form, we will back to you once we got your

message.

Leave a inquiry for machine that turns plastic back into oil: